1. Hydrates and Hydrate Composition

A hydrate is a physical combination of liquid water

and other smaller molecules to produce a solid which has an ice-like or dirty

wet-snow appearance but possesses a different structure than ice.

They are 90% (by weight) water; the other 10% is

composed of one or more of the following compounds: methane, ethane, propane,

iso-butane, n-butane, nitrogen, carbon dioxide and hydrogen sulphide.

The simplified structure of the hydrate crystal is

water molecules with the smaller hydrocarbon molecules occupying spaces between

the water. In a sense, the water molecules trap the hydrocarbons in a crystal

lattice.

Hydrates have specific gravities ranging from 0.96 to

0.98 and therefore float on water and sink in liquid hydrocarbons.

Hydrates are found in most areas of a gas producing

operation:

-

Downhole,

-

Gathering systems

-

Processing systems

Hydrates are a constant challenge in producing natural

gas and must be considered in all designs and production practices.

2. Hydrate Formation

Dangers

and problems created by Hydrates

An obstruction caused by a hydrate formation

can:

a)

reduce or block flow

b)

increase back pressure

c)

increase differential

pressure through a process

The pressure differential across a hydrate “plug” can cause it to

break loose and travel down the pipe at

very high velocities. People have been killed by hydrate plugs dislocating and

smashing through process equipment.

Hydrates can form single or multiple plugs in

lines.

The

formation of hydrate plugs can cause pressure to be trapped between two plugs.

Once formed, hydrates cause a threat to

personnel and equipment if not handled properly during removal. Pressure on both sides of a plug must be

reduced to keep it from dislocating and moving to the low pressure side.

The conditions that affect hydrate

formation are:

®

Pressure

®

Temperature

®

Composition

®

Gas must be at or below its

water dew point or saturation

condition

Note that when the natural gas is in the reservoir, it is assumed to be in

contact with water at equilibrium. The

gas is saturated with water. Therefore, even if free water is not present,

changing the conditions (pressure or temperature) can cause free water to form.

An example of changing the conditions would be passing the gas through a choke.

Pressure

and Temperature

Hydrates tend to form when the pressure

is high and the temperature is low.

All compositions have different points at which hydrates will form. The

most important point to remember is that it does not have to be colder than 0oC in order to have the

conditions necessary for hydrate formation.

When the formation of a hydrate causes a

restriction in a flow line, the restriction causes a pressure drop. The

resulting expansion of gas causes a cooling of the gas (Joule-Thomson effect).

This scenario is referred to as auto-refrigeration and can cause the

further growth of hydrates until the flow is blocked completely.

Hydrates often form at chokes, orifices, thermowells, bends in pipe etc.

3. Composition

The composition of the gas has a large effect on the formation of hydrates.

e.g. A small amount of propane or iso-butane in methane will cause hydrates

to form at warmer temperatures than in pure methane alone.

The presence of H2S will also affect the formation of hydrates.

When H2S is present in a gas composition, it will result in the

formation of hydrates at warmer temperatures at a given pressure.

The presence of CO2 has a much smaller impact and often reduces

the hydrate formation temperature at fixed pressure for a hydrocarbon gas

mixture.

4. Hydrate Inhibition

It is convenient to divide hydrate formation into two categories:

1)

Hydrate formation due to a

decrease in temperature with no sudden pressure drop, such as in the flow

string or surface line, and

2)

Hydrate formation where a sudden

expansion occurs, such as in flow provers, orifices, back-pressure regulators

or chokes.

A review of the conditions that tend to promote

the formation of natural gas hydrates are:

1)

Natural gas at or below

its water dew point with liquid water present.

2)

Temperatures below the

“hydrate formation” temperature for the pressure and gas composition

considered.

3)

High operating pressures

that increase the “hydrate formation” temperature.

4)

High velocity or agitation

through piping or equipment.

5)

Presence of a small “seed”

crystal of hydrate.

6)

Presence of H2S

or CO2 is conducive to hydrate formation since these acid gases are

more soluble in water than hydrocarbons.

4. Dehydration - Overview

Ø removal of water associated with the production of natural gas.

Ø prevents hydrates and reduces corrosion.

Ø Prepares gas for further processing (e.g. cryogenic)

Ø Removal of free water to prevent accumulations and promote single-phase

pipeline flow.

·

Three major methods of gas

dehydration are commonly used:

a) Absorption (wet)

i) triethylene

glycol (TEG)

ii) diethylene

glycol (DEG)

b) Adsorption (dry)

i) molecular

sieves (commonly called zeolites)

ii) silica

gel (essentially SiO2 in bead or powder form)

iii) activated

alumina (in extrudate or pellet form)

c)

Low Temp Processes

i)

Processes that

intentionally form and melt hydrates (LTX)

ii)

Processes that use hydrate

inhibitors

iii)

Processes that use

mechanical refrigeration

4.1. Absorption

·

dehydration by glycol

absorption is one of the most common methods of dehydration used to bring the

water content of a gas stream to pipeline spec.

·

a common dehy unit

consists of a absorption tower (contactor) in which wet gas is contacted with

lean glycol and a stripper in which heat is used to remove water from the rich

glycol.

·

glycols are used for

dehydration as water and glycol are mutually soluble in the liquid phase. Water

boils at a lower temp than glycol, so “rich” glycol is heated to a temperature

above the boiling point of water but below the boiling point of the glycol.

This creates “lean” glycol.

·

Commonly used in the field

at a wellsite for hydrate and free water protection, or in a plant handling

greater volumes of gas for final pipeline spec drying.

·

The advantages of a glycol

unit over a solid desiccant unit are:

a.

Lower installed costs

b.

Lower pressure drop in the

contacting tower

c.

Continuous process rather

than batch

d.

Glycol make-up is simple

vs. recharging dry beds

e.

Glycol units require less

make-up heat to regenerate

f.

Glycol systems operate in

the presence of contaminants that would foul a solid desiccant.

g.

Glycol systems are

adequate at water removal for most spec’s (except cryogenic processing).

·

The disadvantages of a

glycol unit are:

a.

Very low water dew-points

cannot be achieved

b.

Glycol is susceptible to

contamination

c.

Glycol is corrosive when

contaminated or decomposed.

4.2. Process Description

Gas Stream:

a.

Gas enters inlet separator

and liquids are removed.

b.

Gas enters contacting tower

and starts upward through a chimney tray.

c.

The gas passes through the

trays or packing, contacting glycol as it travels. The water in the gas has an

affinity for the glycol and attaches to it.

d.

The gas exits the tower

through a mist eliminator to the next process or to the flowline.

Glycol Stream:

a.

Lean glycol in the

accumulator is pumped to the top of the contactor tower.

b.

The glycol picks up water

from the gas as it travels down from tray to tray (or through the packing).

c.

The glycol exits as rich

glycol, is warmed through the accumulator and is dumped into the stripping

column of the reboiler.

d.

The rich glycol is heated

in the reboiler by a natural gas flame in a burner tube. The temperature causes

the water to vaporize and exit the stripping tower (where it contacts more

incoming rich glycol).

e.

The lean glycol spills

over into the accumulator ready for its next pass through the contacting tower.

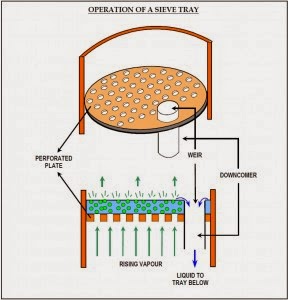

4.3. Dehydrator Components

Inlet Scrubber

- simple two phase separator used to remove

water and liquid hydrocarbons from the wet gas stream.

Glycol - Gas

Contactor

-

vessel in which wet gas is

contacted with lean glycol.

-

utilizes counter-current

flow: gas upward and lean glycol downward.

-

trays exist in the

contactor (valve or bubble cap) to increase the contact time between the wet

gas and lean glycol.

-

mist extractor is located

at the top of the vessel to remove any glycol entrained in the gas.

-

lean glycol is pre-cooled

by a double pipe heat exchanger prior to entering the vessel (glycol can absorb

more water at cooler temps).

-

Glycol should enter the

dehy at about 10o hotter than the gas temperature. If it is too hot,

it can lead to foaming and inefficient dehydration, and if it is too cold,

hydrocarbons can condense in the glycol.

Filter and Pump

-

rich glycol exits the bottom of the contactor and is

filtered prior to entering a pump.

-

filter removes solid

components from glycol in order to protect the pump and decrease operational

problems with fouling of the dehy. unit.

-

the hydraulic pump

utilizes rich glycol from the contactor as the power fluid to pump lean glycol

from the surge tank to the contactor.

Stripping Still

-

the warm rich glycol enters the stripping still

after being preheated in a heating coil (tube side) in the surge tank.

-

The stripping still is usually filled with ceramic

packing or structured packing to improve the surface area contact of the water

vapour with the rich glycol.

-

allows any glycol vapors

to be condensed to eliminate losses.

-

water vapor exits the top

of the stripping still.

-

Fins on the stripping

still condenser section cool the vapor to help drop out any glycol which may be

entrained or vaporized in the water vapor. A temperature just above the boiling

point of water is optimal for the condensing section.

Reboiler

-

vessel in which rich glycol is heated to 175 – 200oC

to vaporize water.

-

heat source is a natural

gas flame in a fire tube.

-

glycol is regenerated to

99% glycol.

-

Glycol regeneration

efficiency can be improved with a “Stahl column”

-

Dry stripping gas (usually

fuel gas) is injected into a column between the reboiler and accumulator

-

The dry gas mixes with the

lean glycol (99%) and strips out more water. Glycol concentrations of 99.9% can

be achieved.

-

The gas enters the

reboiler and exits with the water vapour.

-

The cost to operate a

Stahl column must be weighed against the benefits. The costs are fuel gas (and

hydrocarbon to the environment).

Heat

Exchange/Surge Tank

-

regenerated glycol leaves the reboiler through an

overflow pipe and enters the shell side of the Surge Tank.

-

the lean glycol is cooled

by the rich glycol on the tube side of the exchanger.

-

the surge tank is a liquid

accumulator for the glycol pump to ensure the pump receives a uninterrupted

supply of glycol.

-

A sweet gas blanket is

often maintained in the vapour space above the glycol in the accumulator. A

slight pressure is held which prevents oxygen from the atmosphere and water

vapour from the reboiler from entering.