Separation

of liquids. This is usually carried out

in horizontal or vertical separators that often contain baffles to promote the

coalescence of the liquid droplets that are carried in the gas stream. These liquids are referred to as condensate

and are usually stored at the well site for later removal by truck.

1. Separation Principles

·

Separation of well stream

liquids is by far the most common of all field processing operations and at the

same time, one of the most critical.

·

Well effluent is a

complex mixture of liquid and gaseous hydrocarbons, with water and other

impurities often present.

·

It is necessary to

separate hydrocarbon liquids and water from the hydrocarbon gas.

·

The separation of natural

gas, liquid hydrocarbons, and impurities is accomplished by various field

processing methods which include:

i)

gravity

ii)

heat

iii)

mechanical

iv)

electrical

v)

chemical

2. Separation Processes

A

combination

of these methods is used to separate hydrocarbon gas, liquid and water phases.

1)

Gravity

-

simplest and most common

method in use today.

-

dependant upon the

principle that the liquid components have a greater density than the gas

components.

-

water present is usually heavier than the

hydrocarbon liquid and therefore settles due to gravity.

2)

Impingement

-

relies upon the

difference in momentum between a gas particle and a liquid droplet.

-

takes place when

liquid-laden gas approaches an obstacle and liquid droplets impinge upon the

barrier and increase in size.

-

the effects of gravity

become significant and the drop falls to the liquid section of the vessel.

3)

Centrifugal

-

occurs when the stream to

be separated rotates at high velocities inside a vessel.

-

centrifugal force moves

the liquid to the wall of the vessel where it coalesces and drains to the

liquid section by gravity.

-

Allows a smaller vessel

to be used than other types.

There are two main classes

of separation: Two Phase and

Three Phase

Two Phase

Separation

-

one combined raw product

separated into two distinct products; hydrocarbon gas and hydrocarbon liquids.

-

has an application mainly

in fields with little or no produced water.

Three Phase

Separation

-

Splits the raw well

effluent into three distinct phases or products; hydrocarbon gas, hydrocarbon

liquid and water

-

Used where free water is

produced with the oil or gas stream.

-

Inlet separators at the

gas plant are usually three phase type.

-

Water may be withdrawn by

manual dump or by automatic level control.

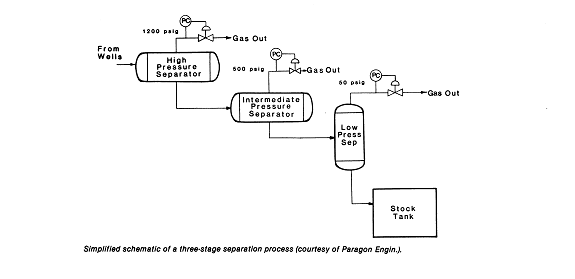

3. Staged Separation of Oil and Gas

-

Pressure is reduced a

little at a time, resulting in a more stable stock tank liquid.

-

A large pressure drop can

cause a reduction in stock tank liquids.

-

The objective is not to

lose valuable LPG’s. C3, C4

and C5 to the hydrocarbon gas phase.

Discussion

1.

Give an example of

3-phase separation.

2.

Where might a 2-phase

separator be used?

3. Theoretically, what would be the best way to separate hydrocarbon liquid

from hydrocarbon gas?

4. Separators

Separation is defined as

the division of the phases present in a hydrocarbon stream to:

a)

obtain more pure liquid

and gas products

b)

allow testing or metering

of the individual phases

c)

ensure that downstream

equipment or processes are protected from exposure to components of the

hydrocarbon stream. For example, condensed hydrocarbon liquids should be

removed from compressor suction lines

d)

isolate the downstream

equipment and processes from the field

A properly designed

separator will provide a clean separation of free gas from the free hydrocarbon

liquids. A separator must perform the

following.

a.

Cause a primary phase

separation of the mostly liquid hydrocarbons from those that are mostly gas.

b.

Refine the separation

process by removing most of the entrained

liquids from the gas.

c.

Further refine the

separation by removing the dissolved

gases from the liquids.

d.

Discharge gas and liquids

into clean production streams.

4.1 Types of Separators

The terms “flash drum”, “Free water knockout (FWKO)”, “accumulator”,

“scrubber”, “traps”, “slug catcher” and “inlet separator” are all terms for

separators used for specific applications.

The selection of the type of separator is dependent on several factors

including:

-

Gas to oil ratio

-

Emulsion tendency of the

HC gas, HC liquid and water

-

Possibility of large

liquid “slugs”

-

Available room, both equipment footprint and

height restrictions.

4.2. Vertical Separators

-

common type of separator

in the oil industry.

-

used when there is either

a very high GOR (scrubbers) or a very low GOR.

-

the inlet stream enters

near the midpoint of the vessel.

-

can provide either two

phase separation or three phase separation.

4.3. Horizontal Separators

-

most common application

is in streams with relatively high gas/oil ratios.

-

gas/liquid interface area

is large which results in a quicker gas breakout

-

the double barrel type

consists of an upper separation section and a lower liquid retention and level

control chamber.

-

Tend to require a large

“footprint” so space can be a limitation (offshore for example.)

4.4. Spherical Separators

-

Commonly used for

separation of small amounts of liquid from large volumes of gas.

-

The advantage of a

spherical separator is that it is more compact for a given gas flow than other

separators.

-

Almost never specified

any longer because of difficulties ($$$) in fabrication with no significant

advantage other than size efficiency and pressure containment.

4..5. Slug Catchers (or Inlet Separators)

-

horizontal separators

located at the inlet of a gas processing facility.

-

removes entrained liquid either not

removed at the well site or formed by dropping temperature in the gathering

system.

-

protects the operation of

downstream equipment from liquid slugs originating in the pipeline system

resulting from changes in pipeline flow rate.

-

isolates the plant from

transient conditions in the field.

4.6. Sections of a Separator

No comments:

Post a Comment